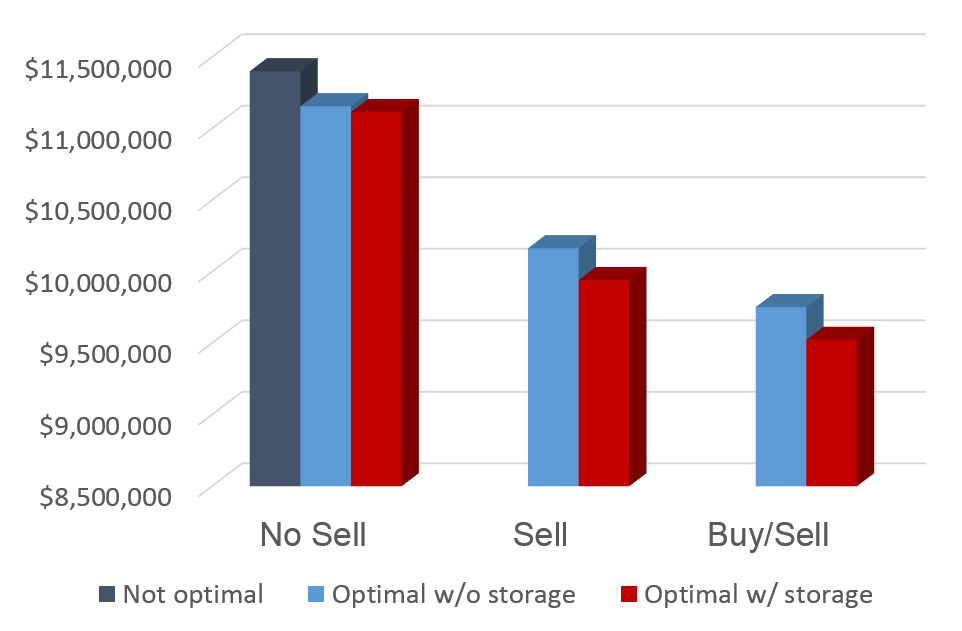

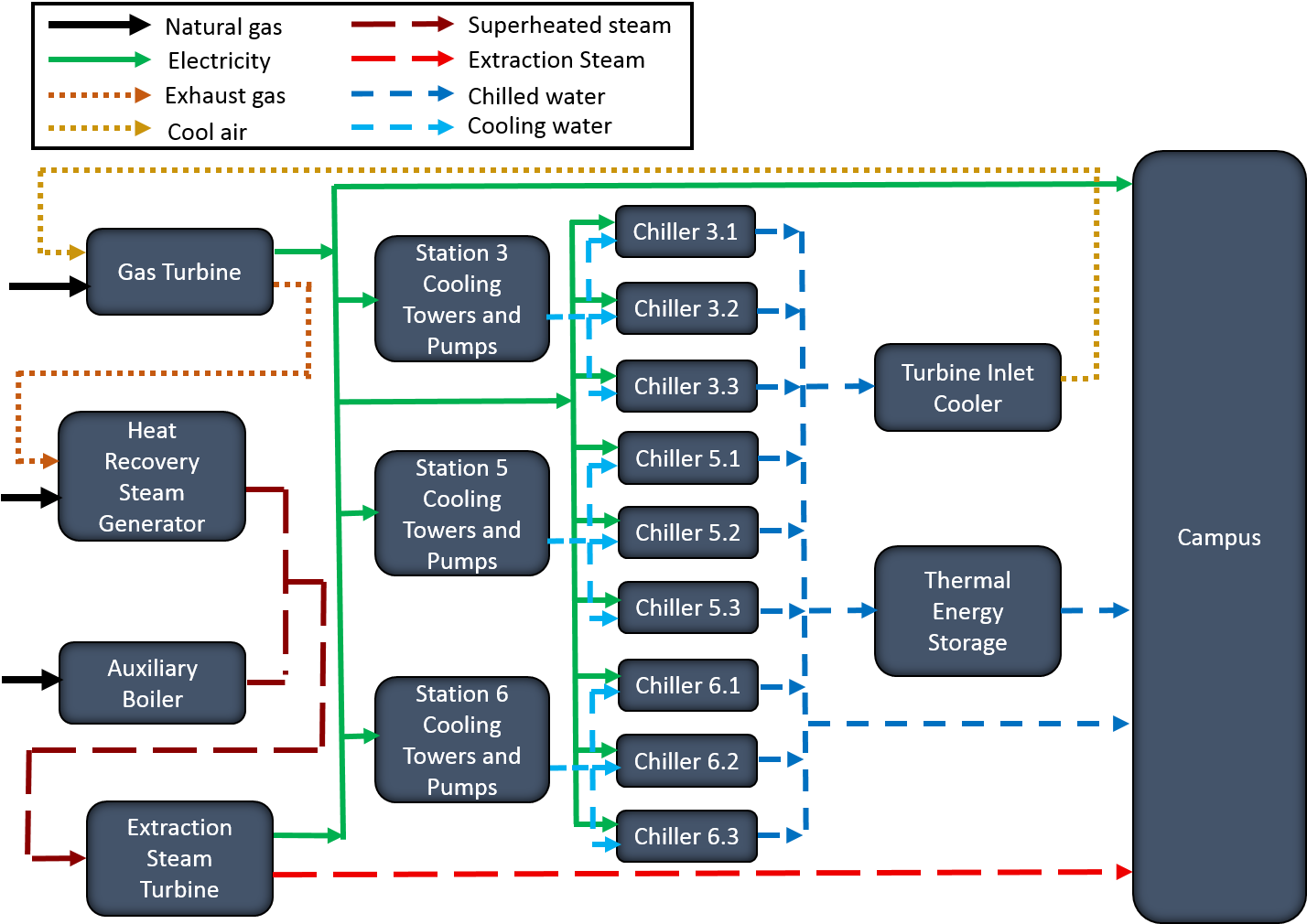

Combined heat and power (CHP), also known as cogeneration, is the simultaneous production of electric power and steam, which can be used as industrial process heat or for space heating. CHP plants work in district energy systems, where heat can be delivered in the vicinity of the plant. CHP plants contain many different types of equipment, often with built-in degrees of freedom. Because electric and heating loads (or prices) are constantly in flux, optimizing the system requires a technology called real-time optimization (RTO) where the latest environmental conditions (temperatures, loads, prices) are updated in real-time and optimal values of operational parameters are solved for accordingly.

Because district energy systems interact with both the electric grid and the thermal components of the system, thermal energy storage can be used in these systems to act as a surrogate for electrical energy storage and be much more cost effective than batteries. The addition of energy storage also gives the system enhanced flexibility so that system performance can be optimized on a dynamic basis.

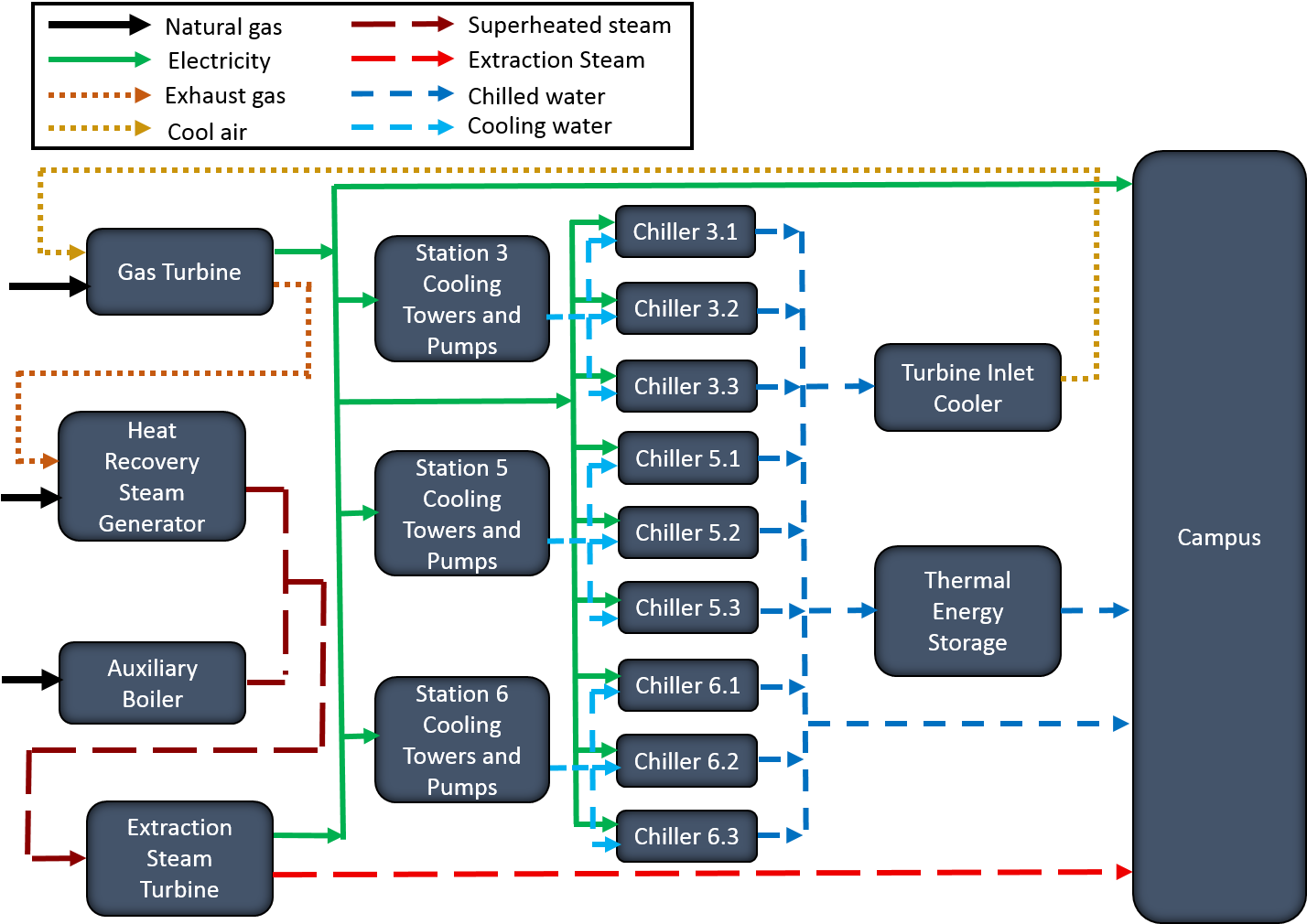

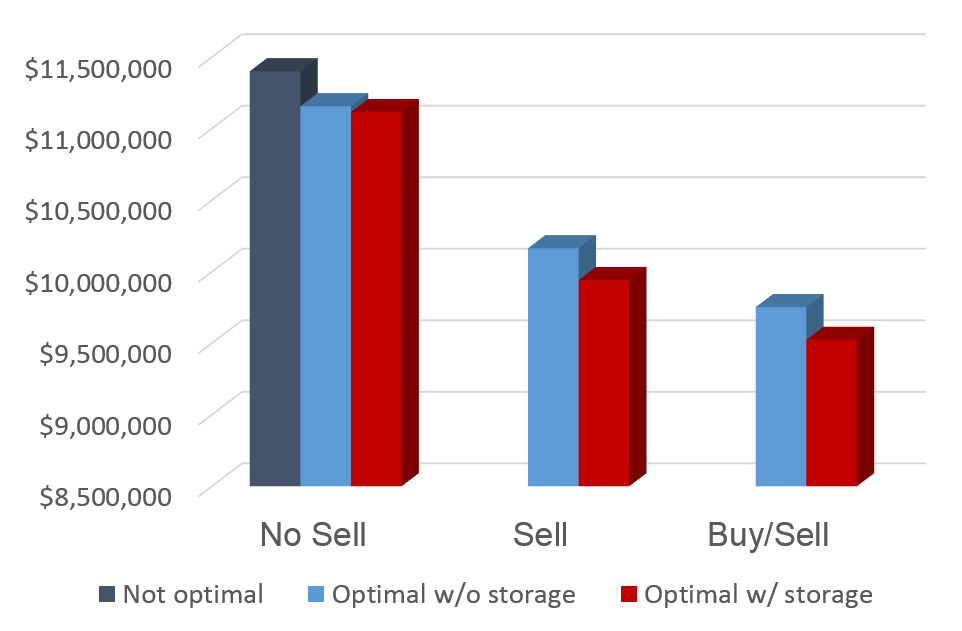

Using this strategy, the system can take advantage of real-time price changes in the electric grid. For example, the system can generate power and store energy when prices are low, which frees up capacity to sell excess power when prices are high. In the figure below, a savings of over 16% can be achieved if a CHP plant participates in the real-time electricity market and used thermal energy storage to improve performance.

Read more here:

Heating, cooling, and electrical load forecasting for a large-scale district energy system

Optimization and advanced control of thermal energy storage systems

Turbine inlet cooling with thermal energy storage

Maximization of energy efficiency of a combined heat and power plant

Nonlinear model predictive control for a heavy-duty gas turbine power plant

Current and Future Work

I have worked at one of the largest oil and petrochemical complexes in the world. CHP is used as an economical way to provide electricity and process steam for the entire complex. The plant interfaces with the electric grid through interconnects that allow the complex to buy and sell power at real-time prices. The complex uses a real-time optimizer for utilities that is constantly monitoring energy prices and process performance to determine optimal setpoints for the plant to use. This real-time optimizer feeds down setpoints to a set of model predictive controllers that help the plant make stable and effective transitions. Although dynamic RTO is not currently done, I am pursuing opportunities to take advantage of electric price forecasting to allow the utility system to pro-actively respond to changing conditions through dynamic optimization.

Because district energy systems interact with both the electric grid and the thermal components of the system, thermal energy storage can be used in these systems to act as a surrogate for electrical energy storage and be much more cost effective than batteries. The addition of energy storage also gives the system enhanced flexibility so that system performance can be optimized on a dynamic basis.

Using this strategy, the system can take advantage of real-time price changes in the electric grid. For example, the system can generate power and store energy when prices are low, which frees up capacity to sell excess power when prices are high. In the figure below, a savings of over 16% can be achieved if a CHP plant participates in the real-time electricity market and used thermal energy storage to improve performance.

Because district energy systems interact with both the electric grid and the thermal components of the system, thermal energy storage can be used in these systems to act as a surrogate for electrical energy storage and be much more cost effective than batteries. The addition of energy storage also gives the system enhanced flexibility so that system performance can be optimized on a dynamic basis.

Using this strategy, the system can take advantage of real-time price changes in the electric grid. For example, the system can generate power and store energy when prices are low, which frees up capacity to sell excess power when prices are high. In the figure below, a savings of over 16% can be achieved if a CHP plant participates in the real-time electricity market and used thermal energy storage to improve performance.

Read more here:

Heating, cooling, and electrical load forecasting for a large-scale district energy system

Optimization and advanced control of thermal energy storage systems

Turbine inlet cooling with thermal energy storage

Maximization of energy efficiency of a combined heat and power plant

Nonlinear model predictive control for a heavy-duty gas turbine power plant

Read more here:

Heating, cooling, and electrical load forecasting for a large-scale district energy system

Optimization and advanced control of thermal energy storage systems

Turbine inlet cooling with thermal energy storage

Maximization of energy efficiency of a combined heat and power plant

Nonlinear model predictive control for a heavy-duty gas turbine power plant